SERVICES

Ace Air Manufacturing reviews your job from your purchase order to our shop order, to final inspection and on time delivery, with complete documentation and certifications. For many years, our company has been approved to implement a wide variety of Quality Systems by major prime aerospace customers.

Ace Air maintains a quality system that is certified to SAE AS-9100D Aerospace Basic Quality System Requirements. We use our internal audit program to provide feedback to management as to the effectiveness of the Quality Management System and to continually make refinements.

Our mission is to be the finest machining center in this region, and to continually strive to improve the quality of our products, workforce, processes, delivery times, and prices.

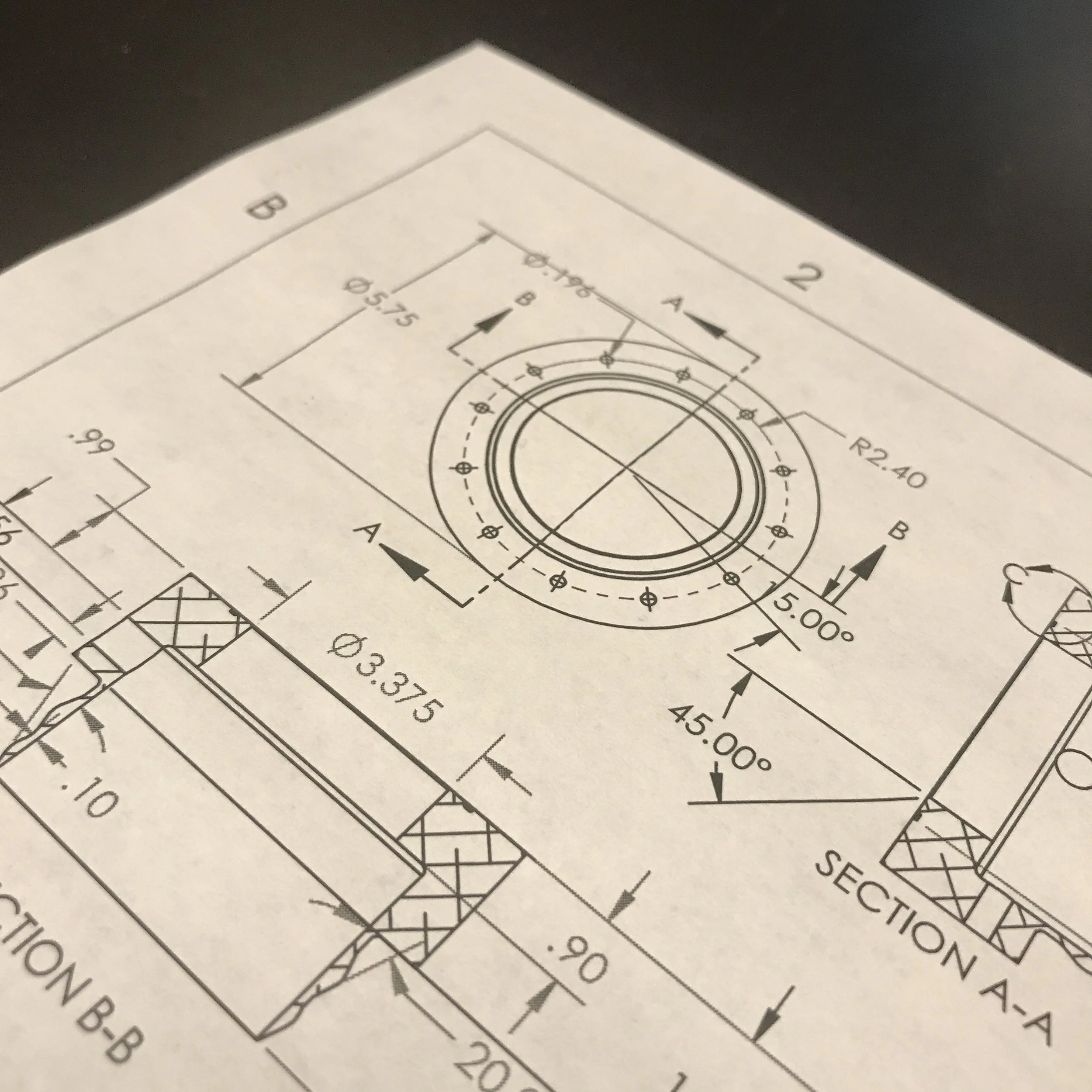

We maintain the latest state of the art programming software to ensure the quality of our machining programs. We utilize the latest programmable Coordinate Measuring Systems to ensure the quality of our machined parts.

Our company utilizes CNC Lathes with tail stocks and CNC Mills with 4 axis capabilities to machine complex, close tolerance parts; from castings and forgings to plates and bar stock. All completely fixtured and tooled.

Our CNC Lathes can machine up to 21 inches in diameter and 26 inches in length. We have a bar capacity of 3 inches with 30 inches between centers, 3400 spindle RPM, 30 HP. Turret has 12 stations BOT.

Our CNC Mills have up to 8100 spindle RPM, 20 tool capacity, and a working envelope of 50 inches x 20 inches x 25 inches XYZ.

We use an advanced, internal Material Requirements and Planning (MRP) system to control our operations. We start with the receipt of our customer’s purchase orders, to planning, scheduling work flow through the manufacturing floor, including placing purchase orders with our external suppliers and finish with delivering machined parts to our customers.

We strive to provide our customers with the best total processing of their order, not just machining their part. We go the extra step to make sure their part meets ALL of the drawing requirements. We know that our customers look for suppliers who bring more value to manufacturing their product. To do this, we have developed a comprehensive Supply Chain of Companies that are NADCAP accredited to provide these extra services.

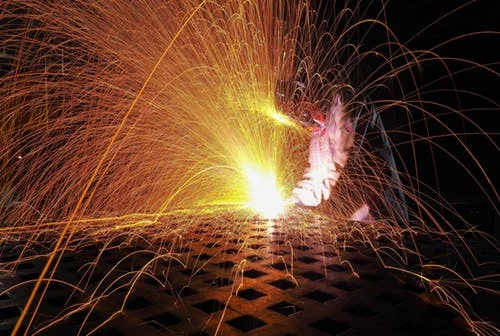

These services include heat treating, sand blasting, shot peening, mechanical testing, non-destructive testing, anodizing, chemical film application, dry lube, passivation, masking, priming, pressure testing, painting, furnace brazing, and welding.

We do minor assembly work at our shop, like installing threaded inserts, pins, bushings, liners, and brake pads.

We manufacture and machine many aerospace parts and assemblies that are intricate and easily damageable if not protected properly.

If shipped in improper or poor quality packaging, these parts are put at risk. For example, packaging that is too large allows parts to move, causing nicks and scratches to appear on the metal. Likewise, packaging that is too small can cause parts to protrude through the wrapping, causing dents or breaking of edges.

We ensure our customers receive a quality part that meets all of their requirements when they open their shipping containers at their facility. We invest in first-class shipping materials using expanded foam packaging, padded packing paper, and bubble wrap to meet our customer’s expectations.

Our customers deserve to receive their parts on time and in pristine condition.

We partner with our customers, and in doing so, we establish long term contracts with them. This allows us to maintain an electronic data interchange (EDI) system linked to our customers’ internal database to obtain forecast requirements, which help plan our shop’s machining schedules, obtain purchase orders, invoices, etc. This capability allows us to package, deliver, and ship thousands of precision machined parts to our customers each year.